TWS is a Great Training Option for Everyone

Learn more about how we can prepare you to advance your career.

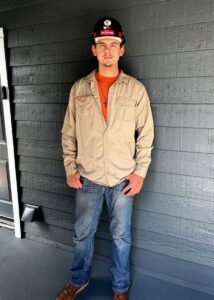

Connor, 19, from Martinsburg, West Virginia, completed the Professional Welder program at Tulsa Welding School in Jacksonville in February 2024.

Thanks for your time, Connor. Did you enroll at Tulsa Welding School straight out of high school?

Thanks for your time, Connor. Did you enroll at Tulsa Welding School straight out of high school?

I graduated high school in June and moved down here. I was down in Florida for about a month before I started class in July 2023.

How was moving out of state at 18? Did you come down to Florida on your own?

Have You Considered a Career in the Skilled Trades?

Fill out the form to recieve a no obligation info packet.

Actually, I was with my girlfriend, now fiancée. We moved down here, as her family lives in the area.

A fiancée and finished with trade school at 19, you’re in a hurry! Why did you choose welding school?

So, in my sophomore year I had a vocational agriculture class. My instructor had a group of seniors in that class who were pretty good at welding, but they were moving on as they were graduating. He needed to get some other kids in there to try to grow an interest in it. I joined with another classmate and started to get into it. He had us do some projects, little things at the time, and after the first two weeks of welding, once I actually started getting the hang of it, I really enjoyed it. So, I decided to continue with welding through my remaining years of high school. I knew I wanted to go to a trade school from then on.

You can’t beat the influence of a good teacher. What’s his name?

Christopher Vandine. He even opened up a private class for me in my senior year. So, I had two class periods in my senior year where I did nothing but weld. Mr. Vandine helped me because I was pretty good, compared to other people, and he saw that I had a lot of interest in it. It’s all I wanted to do. So, he worked out a way for me to have that opportunity to weld as much as I could.

New: Industrial Maintenance

Learn About Our New Advanced Industrial Maintenance Program

Tulsa Welding School is proud to announce our newest program offering available at our Houston & Dallas Metro Campuses – Advanced Industrial Maintenance Technology! Learn the skills you need to take on the industries of manufacturing, distribution, energy production and facility maintenance in as few as 7 months.

Thank you, Mr. Vandine! What did you enjoy most about your time at TWS?

I enjoyed the instructors. If you needed help, at least the ones I asked, they were there for you. They were more than willing to help you out, to show you what to do. I think there was only one instructor that I didn’t really connect with. So, that and then meeting some really good people from all around the country was probably my favorite part of the experience.

With that high school welding experience, how was the program? Did you find it easy? Frustrating?

It was pretty straightforward. I’d done most of the processes except for TIG and Flux Core; in high school I did a lot of Stick and MIG. So, I flew through the first two phases because they were kind of second nature to me. Obviously, the school helped me identify little things that I could tweak, but I’d say it was pretty easy. I did have days, obviously, that I struggled, but I never thought, “I don’t want to do this anymore.”

How did you deal with those days that you struggled? Any tips to share?

Honestly, one, just taking some time. If I get frustrated with something, I’ve got to take a second or two away from it. If I keep trying to push at something, I’m just going to keep messing it up even worse or I’m eventually just going to throw my hands up! Other than that, I’d grab an instructor and we’d sit there and look at it. We’d go over it and he’d give me some tips. So, taking advantage of a straight one-on-one with an instructor, and just taking a second to breathe is probably what got me through it.

So, you graduated four months ago, where are you working?

I work for BAE Systems as a welder. I started on March 3, two weeks after finishing welding school. It was pretty cool, because talking with Tracy and the Career Services people at TWS, they said it’s very rare for TWS graduates to get hired on with BAE Systems as a welder right off the bat. A lot of graduates start off as fire watchers or helpers. I guess they were trying to warn me not to get my hopes up! But I went in there, took a weld test, and I got on as a first-class welder, right out the gate.

Congratulations! What are you doing there? Can you tell us?

When I started, they saw my potential. So, in the three months since I started, I’ve got seven certifications through them. I’ve been taking as many certifications as I can. I was in their test facility for about six weeks and then they had me work on some boats for a month, mainly LCS ships and destroyers. But right now, we have a contract with General Dynamics Electric Boat, so I’m working for them through BAE Systems. Technically I’m going to be an employee of General Dynamics, but still under BAE’s payroll.

That’s pretty cool. Is that a permanent shift?

I believe it’s a ten-year contract, so we’ll see. I’m traveling up to Georgia every day right now, and we’re doing submarine modules. It’s about a 45-minute drive, so it’s not awful. But this whole thing of going to Georgia is temporary. We’re clearing out three bays at our BAE steel shop in Jacksonville to be able to move all the work there. So, we’re up in GA right now to learn all the paperwork and how everything rolls.

That sounds pretty exciting.

It’s pretty cool work, yeah. You can see where this stuff’s actually going to go in the subs. It’s pretty cool stuff and it feels like I’m doing something important.

Are you happy with the money you’re making?

Yeah, I’m pretty happy. I can’t complain. I obviously see a lot of potential with big companies like this – I can see the possibilities of moving up. There’s also going to be a pay increase for those of us who took the opportunity to go to Georgia for training. They’re talking about a $5-$7/hour pay raise. So, either way, we’re going to be on top of the other guys because of the specialized training they’ve got us in.

At 19, you’ve got a long way ahead of you, but what’s your career plan from here, Connor?

I’m going to work my way up through the company as far as I can. If the opportunities are there to take big leaps to different positions, then I’ll go for it. If I could be a supervisor or even a manager, then I‘d go for it. Maybe an inspector one day…I wouldn’t mind that either. Honestly, to go as high as I can go here is what I’m aiming for. It’s a good company and we have big contracts coming through all the time, so the work’s going to be endless. Our biggest customer is the Navy and well, the Navy’s never going to go away.

What do you enjoy most about this new trade?

I think the biggest thing is the satisfaction that comes when I put down a good weld. It just makes me feel good, especially when a CWI [Certified Weld Inspector] comes through to do an X-ray on a weld, and they say that looks good. It’s just that the satisfaction of that, and then getting compliments as well. It makes you feel good. It’s nice to feel you’re good at something.

Did you make some connections at school, people you’ll stay in touch with?

Yeah, there are two guys. We talk from time to time. We haven’t seen each other in person for a minute. We saw each other at graduation, but we’re all working 40/50-hour work weeks, so it’s a little hard. We definitely stay in touch and talk though. It’s good to stay connected as you never know what will come up.

What advice do you have for a student to be successful at Tulsa Welding School?

When you get a project completed and it gets graded, if you have the time, do it again and try to get a better grade. Try to better yourself all the time. I know a lot of people who got a grade, they took it, and they were done. Let’s say they got a 70, and they’re like, okay, and they took it. But when I was in school, I hated getting below a 90 on a project. Anything below a 90, I automatically redid it. It’s just one of those things; keep doing your best, keep trying to improve yourself. Don’t get too loose on yourself, don’t get complacent. You can always try to do better. A barely passing grade might get you a welding job because the world needs welders, but it isn’t going to get you a job at BAE Systems.

If you’re a TWS graduate and would like to share your success and be an inspiration to others, please email [email protected] to be considered for a Graduate Connection interview. Please include details such as your graduation date (month/year), program, and campus name (Tulsa/Jacksonville/Houston/Dallas).