TWS is a Great Training Option for Everyone

Learn more about how we can prepare you to advance your career.

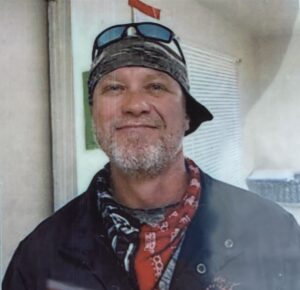

Lou, 49, originally from Middelburg, South Africa, moved to the U.S. in 2000. Lou completed the seven-month Professional Welder program at Tulsa Welding School in Jacksonville in September 2023.

Thanks for your time, Lou. Tell us what you did before coming to Tulsa Welding School?

Thanks for your time, Lou. Tell us what you did before coming to Tulsa Welding School?

Long story short, after high school I went to the Army in South Africa. After my military services I then took three years to get into a dental technician school and did a four-year bachelor’s degree there. I was highly qualified because that school only took 30 people a year out of 800 applicants. That’s why it took me three years to get in. In the years I didn’t get in to the school, I’d go back to working in a coal mine.

After school, we wanted to leave the country. So, a friend and I went to see an old crown and bridge lecturer in Sarasota for two weeks. We were in Sarasota, finished in Miami, and I said, “I love America! The grass is greener, the cars are bigger, I want to go to America!”

Have You Considered a Career in the Skilled Trades?

Fill out the form to recieve a no obligation info packet.

I got sponsored to come over to America in 2000 as a Certified Dental Technician. I made orthodontic appliances, implants, and facial prosthetics. I’ve been here in Jacksonville since and I’m now a U.S. citizen. I worked for a guy for 12 years before he unfortunately passed away. He and his wife died in the Bahamas in a plane crash. After that I opened my own dental lab, and then my lawn & landscaping business. I haven’t been back to SA in 20 years. My sister is still there, but I have no other family. One of my dental tech classmates, Elisabeth, came over after I got here, and we are married. But everything changed in 2020.

What happened in 2020, if you want to share?

I was in an auto accident that nearly killed me and led to four surgeries. It took me a year to walk again. I was in my truck with my crew pulling a trailer of equipment. I was doing 60mph and t-boned a guy who pulled out in front of me. The second surgery led to an infection. They thought they might need to amputate my leg. They didn’t, but I could never go back to doing what I was doing, which was landscaping work. That year was specifically bad because my wife’s breast cancer that had been in remission came back a month after my accident, and then she had thyroid cancer. I also lost my dad back in South Africa.

Wow, that’s a rough year. Our condolences. Where did the idea of welding come from?

Once I got back on my feet, one of my great landscaping clients gave me a chance. He and his son started a pipe company called Central Pipe Rehab. They paid me what they could as a general laborer, but the welders were getting paid more. I was helping this one guy, Lee, on a job in Virginia; everybody was doing stuff and he asked me to help him with some welding inside a 72-inch pipe that we’d hammered under the railroad. It took two welders eight hours to weld a single joint, and then hammer the next section. This is how bad a welder I was – Lee said to me, “I’ll pay you $20 if you can just STOP what you’re welding right now.” I was that bad! I knew then that I needed to go to welding school for two reasons; first if I wanted to get paid more than a laborer, I needed a trade, and second, I felt I had to redeem myself as a welder. That guy Lee doesn’t even know I’m a certified welder now!

New: Industrial Maintenance

Learn About Our New Advanced Industrial Maintenance Program in Houston

Tulsa Welding School is proud to announce our newest program offering available at our Houston Campus – Advanced Industrial Maintenance Technology! Learn the skills you need to take on the industries of manufacturing, distribution, energy production and facility maintenance in as few as 7 months.

You should try to find him! What did you enjoy most about your time at TWS?

The freedom to focus and learn. My only job was to stay in school and weld. I was the oldest in my class and my welding skills were absolutely deplorable. I didn’t know what the hell I was thinking! But I did hear Jimmy Naro, our instructor on our first day, say, “You are in Tulsa Welding School where you get the privilege of practice. If you want to get good at welding, you’ve got to practice.” I took note of that.

There were three classes to pick from – morning, afternoon, evening. I picked the morning class. I’d be in class from 7am to 12pm. I knew I needed practice so I decided I would not weld less than a hundred rods a day. I’d stay in class until lunchtime, then stay in my booth until nighttime. Often, I’d leave around 7pm, but sometimes I’d go home only when the school closed after evening class. There were a lot of burns, a lot of learning, and a lot of practice. I had an opportunity, and I was going to use it. Any free time I had, I practiced. Sometimes I’d also go in on a Saturday and Sunday. I wanted to be good, not just average.

Good for you. Did all that hard work and practice pay off?

I was the worst welder when I started in February, 100% for sure the worst. I got a scar on the back of my neck where slack fell in the back. I got burned, I went through jackets. I was terrible, absolutely terrible. You took a chance just coming into my booth! I was that bad. But I ended up with a 4.0 GPA, the President’s Award, and finished top of my class in September. Graduation in November felt good, man! I put in the work. My seven-month program would’ve been just the morning class, but I tripled that. The only way I did it is by staying with the next class, and sometimes the next class after that. I was there a lot, and physically it was hard on my foot after the accident. But I read something in the hallway, “You’ve got to be willing to push yourself.” And I did. But I can tell you this, I still have a lot to learn. That’s the beauty of this thing called welding. Don’t get stagnant, don’t think you are very good and have nothing left to learn.

Did you have any frustrations on the program?

Look at Tiger Woods. He started as a kid and he had a true gift for golf, but I have not met a welder that was born a welder. To be good, you have to be willing to put in the hours. A big thing is asking questions; I had great instructors and they helped me a lot – Shane Murphy, Jimmy Naro, Joe Rush, and Jack. I spoke with a lot of the best instructors, and they all had the same story when I asked them if they were great from the beginning, “Of course not!” or “Hell no!” were the usual answers.

My secret to overcoming frustration was believing what Jimmy has said on day one, “You’ve got to practice, practice, practice…” But don’t practice just to practice, practice with purpose. Reflect on what happened with each weld. There are simple rules, it comes down to basics. My problem was overthinking it. That overwhelmed me. But I knew I had the instructors and if I struggled, trust me, they were in my booth all the time when I had an issue. But they couldn’t fix it, I had to fix it. I’m the one struggling. They will show you, they’ll even hold your hand, but they can’t do it for you. You have to solve it through practice. Often what’s holding you back is just a little thing. And usually, for me, it was because I was uncomfortable.

So, tell us about finding a job after graduation.

Honestly, I could write a story of nightmares. I began to question the career path I’d taken in my first hiring experiences. My first job lasted a week. I’ve never been fired in my life and that job I got hired and fired and I never welded once. I was taken advantage of, and the guy actually wanted me to come back! I had another setback in another job welding aluminum – the guy had a heart attack and that whole set up was just a mess after that. I went back to Ms. Tracy’s office in Career Services and cried on her shoulder. I love Ms. Tracy, all praise to her. I did well in school, but I was discouraged because I couldn’t get a decent job. Ms. Tracy was like a mom, a great communicator. Ask her to show you all her special candy that she has in the back because I was in there a lot! She never quit on me, and we became good friends. I was very lucky to have her as my Career Services Advisor. She’s got a great voice too…she sang the anthem at our graduation! Anyway, Ms. Tracy gave me some candy and told me to relax, that we’d find me something. Anyway, I must have sent my résumé to 50 companies on Indeed, and on my lowest day, I got a phone call…and the amount of money I’m making right now is insane.

That’s great. You persevered. Where are you working?

The company I’m working for is called Midwest Mole, a construction, drilling, boring, and tunneling company out of Greenfield, Indiana, with projects across the country. I’m in Orlando right now. I’m speaking to you from my room in the Hilton, about 10 minutes away from Disney. This is my second week.

That’s awesome. You mentioned the “insane” money earlier. Would you like to share?

I’m getting paid close to $40/hour right now, starting out, with full benefits – health, dental, vision. I’ll even get stock options after a thousand hours. I haven’t welded yet, but now that I have school under my belt, they wanted me. What I’m saying is that life takes you with it sometimes, but it kind of always brings you back. I work 50 hours a week and I get paid overtime. I’m so, so blessed.

What’s your career plan from here?

I love the company. We had the big bosses come in today and they treat their employees really well. If you look at their website, their employees are what matters. It says it right there. My plan is to stay with this company. I love the people here. They had me taking air samples with a trash bag because that’s part of the initiation. There is no such thing as an air sample in a trash bag! But it’s super, super hard work. You’ve got to think on your feet and have the right attitude. They’re looking for the best. So, what I’m saying is, develop your skills.

What advice do you have for someone to be successful at Tulsa Welding School?

Appreciate your life and be grateful. I have lots of things under my belt, but I’ve also learned that it can all be taken away from you in a second. So, take advantage of the wonderful opportunity you have to be at Tulsa Welding School. Practice, practice, practice, and ask questions. Don’t just clock in and clock out. Sacrifice, do your best, and be willing to push yourself. Sometimes if you sacrifice and do your best, the right people will see it, and it will make a real difference to your life.

Unfortunately, I saw people taking shortcuts at school. There’s no shortcut to becoming a good welder – unless you’re the Tiger Woods of welding. Even Tiger would say you’ve got to practice; you’ve got to put in the time. I was the oldest person in class. But because I’m older, I know that time is the most important thing we have in life…it’s not money, it’s using your time the right way.

And when you graduate, if you don’t get that dream job to start with, keep persevering, put in the time, don’t give up. Sometimes life will give you lemons, but if you’ve put in the work and developed your skills, you will find your way.

If you’re a TWS graduate and would like to share your success and be an inspiration to others, please email [email protected] to be considered for a Graduate Connection interview. Please include details such as your graduation date (month/year), program, and campus name (Tulsa/Jacksonville/Houston/Dallas).