TWS is a Great Training Option for Everyone

Learn more about how we can prepare you to advance your career.

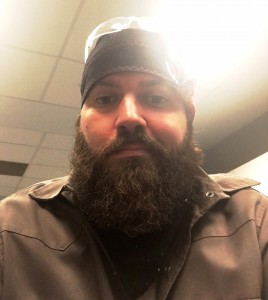

Mark, 38, from Charleston, SC, now lives in Brandon, SD. Mark graduated from the seven month Welding Specialist program at Tulsa Welding School & Technology Center in Houston, TX, in February 2017. Mark had zero prior welding experience before he enrolled in the program in the summer of 2016.

Mark, 38, from Charleston, SC, now lives in Brandon, SD. Mark graduated from the seven month Welding Specialist program at Tulsa Welding School & Technology Center in Houston, TX, in February 2017. Mark had zero prior welding experience before he enrolled in the program in the summer of 2016.

Thanks for sharing your story, Mark. How did you come to welding in your late 30s?

It was a career change. I’d been working at car dealerships, I was a service advisor with Subaru. I moved to Houston for a job lined up by the manufacturer’s district reps, but the service manager at the dealership couldn’t hire me for six months. I needed to find something to do, and I’d always had an interest in welding and fabrication. I thought why not take the opportunity?

Where did the interest in welding & fabrication come from?

Have You Considered a Career in the Skilled Trades?

Fill out the form to recieve a no obligation info packet.

Just through friends who had body shops or were motorcycle mechanics. Also, from watching stuff on the Discovery channel. It looked pretty cool. I had no welding experience whatsoever. I’d only seen it done. I’d never actually done it before I started at the school.

What did you enjoy most about Tulsa Welding School?

The instructors were very accommodating; everybody there is willing to help you out. You can just grab any instructor and they’ll come help you. It’s actually good to get different input from other instructors because they may do things a little differently that may work better for you. Here’s a perfect example: In one of the phases, I had an issue running a root pass: a different instructor helped me out and I got it.

How easy was it to get a job after graduating?

I got a job before I was even done with my program. I got it about two weeks before the end of school. It’s the company I’m with now – Marmen Energy in Brandon, South Dakota.

New: Industrial Maintenance

Learn About Our New Advanced Industrial Maintenance Program in Houston

Tulsa Welding School is proud to announce our newest program offering available at our Houston Campus – Advanced Industrial Maintenance Technology! Learn the skills you need to take on the industries of manufacturing, distribution, energy production and facility maintenance in as few as 7 months.

That’s great. How did you get the job?

Marmen came to the school to do a presentation on the company. They showed us a video, explained a little about the company, what they made and what the job involved. Then, if we wanted to, we were invited to take an aptitude test. If they liked the results, they called you for an interview.

What do you make?

The big wind towers that produce electricity. We make the tower sections and the can. When the contract company, like GE, gets it all on site, they put it together and somebody else maintains them.

What do you do every day?

I got put on a sub-arc welder, so I do very little manual welding unless I’m doing repairs. I spend most of my day in a chair watching a machine weld for me! It’s good though…I have to do a good job picking the right program, adjusting the amps correctly and controlling the speed of the weld. If I do my job well, then we have less repairs due to either imperfections in the weld or visual issues. GE has very strict specifications on how the weld bead has to look – pipes, lips, curvature…everything.

So the better job I do on the sub-arc, the less repairs we’ve got to do. The more cans we can get out, the more productive we are. Even though I’m on a machine, the fundamentals I learned at Tulsa still carry over big time. The fundamentals are the same even though I don’t have a torch in my hand.

Did you get on the job training?

They teach you what they need you to learn. I took a weld test and went through their generic training platform; that’s the basic training of what I would be doing on the floor. Once you’re done with that, you go to the section of the shop where you’ll be working, and they train you on the specifics of that section.

What kind of stuff did they train you on?

We did a lot of grinding and sanding to reshape welding beads to look like they’re sub-arc welded. Sometimes, if you have to repair something, you’re not going to put the can back on the roller and re-weld when you can just do it on the floor with a manual welder. So you spend a lot of time learning sanding/grinding techniques. The training is at your pace depending on how long it takes you to pick it up. Me and a guy from my class in Tulsa did it in two weeks, which by all accounts was pretty quick. I think we definitely had an advantage over some of the other people that they hired.

How’s the money compared to the dealership?

It’s not greatest starting out, but I have zero experience so I wouldn’t expect anything more. But longer term it’s going to be better. But at the same time, because of the results of my weld test, I got a quarter more there on the spot and once you get out of training and move into your scheduled shift, you get a dollar raise. Then after six months I’ll get a cost of living adjustment, so it’ll add up pretty quickly. While the pay is a little low at the beginning, they really hook you up with incredible medical benefits. They pay 95% of my medical insurance. I pay $30 a month for medical, dental and vision. That makes up the difference right there alone.

Where would you like your career to be in three years?

I just started here in March. But in three years, if everything keeps going as well as it is now, I’ll probably still be here trying to move up through the company. It’s a very good company to work for and the area is very nice. There are a lot of opportunities and potential for growth – they like to promote from within.

Many TWS grads take contract work traveling the country from job site to job site, but you picked a more steady lifestyle?

Yeah, having a stable job and be based in one area appealed to me more than all the traveling. I was definitely the oldest in my class. A lot of the guys were fresh out of high school, so more power to them to go do that kind of work. If I was 21, I’d go do that. I’d get a truck and an RV and go drive all over the country for work. I’d have fun and live it up. But I’m turning 40 in two years, so I’m not looking to job hop anymore. I wanted to stay in one place, try and work up through the company, and grow with it.

If you could have any job, what would your dream job be?

Maybe overseas contracting. I was in the Coastguard for six years, so I’d like to go do something with the military overseas, maybe welding for aircraft maintenance…stuff like that.

With your experience in the Coastguard, is that a possibility?

It’s definitely feasible. I met with a company in Houston before I came here. They’d have put me on a crew that they contract out. After I’d been there a year, they said there’d be opportunities to go overseas, but they were still trying to grow their contracts so I had a feeling that the overseas stuff wouldn’t have been guaranteed. So, it’s probably a pipe dream, but I’m happy where I am at the moment.

But did you leave Tulsa feeling you were on your way to becoming a specialist in your field?

Definitely. You definitely leave with the fundamentals for sure, and it clearly showed on my first day at work here in South Dakota. The first day they give you a tour. Then you start working with the trainer who immediately tacks up two plates and tells you to go ahead and run your weld test. He let me run some practice beads to shake the dust off because I didn’t weld for 4/6 weeks before I got to SD. After the test I got an increase in pay because of how well I did on it. If you’re able to pick up some stuff quicker at school, you can really start developing your own methods there before you even get out in the field and head down whichever path you choose.

So you got the job before graduation, but didn’t weld for 4/6 weeks?

They let me pick my start date because I had to relocate to South Dakota from Houston. It was nice to take a month off knowing I had a job to go to.

What advice would you give to new students considering TWS?

I’d have liked to have done more research on the jobs you can get after graduation; then really figure out what’s most appealing. In school you learn pretty much everything anyways, but if you can tell an instructor what you really want to do then, as long as there’s an open booth, you can stay as long as you want. Let’s say you know you want to do TIG welding. Stay after class and talk to a TIG instructor. He can give you all the tips and tricks to really help you master that process, so you can go and knock out a weld test in the field you want to work in.

So, did you make any connections at Tulsa for job hunting?

Yeah, for sure, we had an instructor that really harped on keeping your instructors’ and classmates’ phone numbers in your phone to keep in touch because you never know. If you get fired or your contract ends, you’re going to be digging through your phone pretty quickly. I basically handed out a piece of paper in class and had everybody write their name and phone number on it. Then, I photocopied it for everybody in the class. We even have group chat on Instagram. We send weld pictures to each other.

What do you do for fun?

The good thing is I really like camping, hiking, stuff like that. There’s a campground every 10 miles, so South Dakota was a no-brainer really – this state is like one big national park! Sioux Falls is only 8 miles away. It’s a cool, progressive city that I would equate to my hometown of Charleston, SC. Little coffee shops, little bars, specialty burger restaurants, good shops to buy clothes. It’s just a nice town.

If you were a millionaire for a day, what would you do?

I would definitely buy land – that would be my number one thing. I also love boats so I’d definitely go find a boat…and a nice big RV that I could go cruise around in! If there was anything left, I’d buy a new car.

If you’re a TWS graduate and would like to share your success and be an inspiration to others, please email [email protected] to be considered for a Graduate Connection interview. Please include details such as your graduation date (month/year), program, and campus name (Tulsa/Jacksonville/Houston).

This blog has been labeled as archived as it may no longer contain the most up-to-date data. For a list of all current blog posts, please visit our blog homepage at https://www.tws.edu/blog/