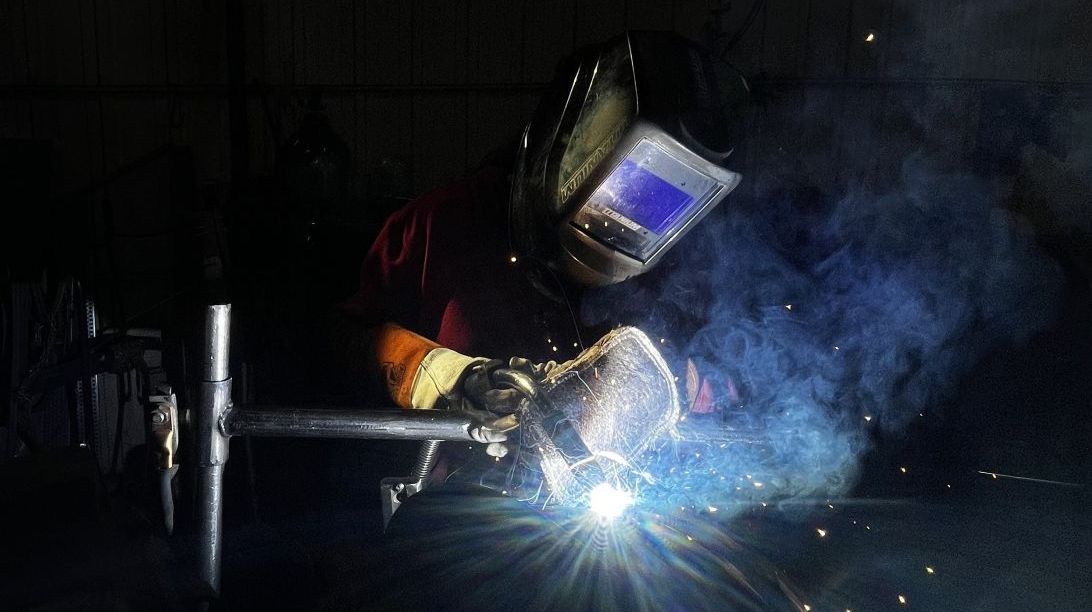

TWS is a Great Training Option for Everyone

Learn more about how we can prepare you to advance your career.

Are you interested in becoming a specialized welder but unsure about which specialty to pursue? The great news is that there are a variety of options available to you, each with its own unique set of skills and applications. Whether you’re drawn to structural welding, metal arc welding, or pipe welding, exploring these specialties can help you identify your passion and career goals. By gaining insight into each field, you can make a more informed decision about the path that best aligns with your interests and aspirations.

The first step to becoming a specialized welder is completing the Professional Welding program at TWS. This will lay the foundation for specialization. You will learn SMAW, MIG, TIG, FCAW, and structural and pipe welding techniques. Plus, you can choose between a generalized welder role that works on various welding projects or specialize in a few techniques and become very proficient in a single environment. So, what is a specialized welder?

What is a Specialized Welder?

Welders have options when it comes to jobs. Each of these roles not only highlight different techniques and applications, but also offer unique opportunities for career advancement and personal growth. Here are several of the specialized welding roles that are available to Tulsa Welding School (TWS) graduates:

Shield Metal Arc Welding (SMAW)

The SMAW technique is also known as stick welding. A welder who specializes in SMAW can weld a variety of different alloys and metals. They use AC or DC current across an electrode, creating an arc to join the electrode and metal. This method is particularly valued for its versatility and effectiveness in outdoor environments and on rusty or dirty materials. Additionally, SMAW is often favored for its simplicity and low equipment cost, making it an ideal choice for both novice welders and experienced professionals.

Have You Considered a Career in the Skilled Trades?

Fill out the form to recieve a no obligation info packet.

Metal Inert Gas Welding (MIG)

MIG welders use electricity to melt and join metal. This process includes an electrical arc, electrode wire, and metal. The arc melts the electrode wire, creating the weld between metals. This is also known for its speed and versatility, making this great for many applications, from auto repairs to fabrication projects. MIG welding is often favored by beginners due to its ease of use and the ability to produce clean, strong welds with minimal cleanup.

Tungsten Inert Gas Welding (TIG)

TIG welders join metal together using tungsten electrodes. The electrode creates an arc that melts the metal into a welding pool. Common metals that TIG welders join include aluminum, stainless steel, steel, and nickel alloy.

Additionally, TIG (Tungsten Inert Gas Welding) is valued for its precision and control, allowing welders to produce high-quality, aesthetically pleasing welds. Moreover, TIG welding is often used in industries that require intricate work, such as aerospace and automotive manufacturing, due to its ability to create strong and clean joints in thin materials.

Flux-cored Arc Welding (FCAW)

The FCAW (Flux-Cored Arc Welding) technique is particularly effective for welding thick materials and metals like cast iron, carbon steel, stainless steel, and nickel alloy. One of its major advantages is its ability to handle dirty, rusted, or contaminated metals, making it ideal for outdoor or industrial environments where surface conditions aren’t always perfect.

In addition, FCAW is known for its deep penetration and fast welding speed, which makes it a go-to method for heavy-duty projects such as shipbuilding, construction, and large-scale fabrication work. This technique is versatile and efficient, especially when high productivity is required.

Structural Welding

Structural welding is the process of joining metal to create structures. It is used to construct infrastructure like bridges and buildings. Structural welding requires precision and strength, as the welded joints must support the weight and forces applied to the structure.

Structural welders play a crucial role in ensuring the integrity and safety of large-scale projects, often working in high-pressure environments where the quality of the welds is critical.

Pipe Welding

A pipe welder is responsible for the construction, maintenance, and repair of pipelines and related metal components. They measure, cut, and weld pipes together to create a pipeline that safely transports liquids and gasses. Precision is key in this role, as even a small error can lead to leaks or system failures, especially when dealing with high-pressure materials. Pipe welders often work in demanding environments, such as oil refineries, power plants, and underwater settings, where the integrity of the welds is crucial for safety and efficiency.

Underwater Welding

An underwater welder uses arc welding techniques to weld and cut metals in a submerged environment. They learn about welding techniques and diving procedures, which are also useful when welding in tight spaces.

In addition to standard welding skills, underwater welders must be proficient in handling the unique challenges posed by working underwater, such as water pressure, limited visibility, and strong currents. Their work is critical for maintaining and repairing structures like offshore oil rigs, ships, and pipelines, often in extreme or hazardous conditions.

- Master welding techniques in water and on land

- Proficient in diving and safety protocols

- Skilled at working in confined or low-visibility environments

The Bottom Line

Ready to choose your welding specialty? The Professional Welder program at Tulsa Welding School’s starts by helping you know what it’s like to be a welder in interactive workshop courses and welding booths. You’ll be trained in structural, flux core, and pipe welding in as little as seven months. You’ll also be prepared to excel in job interviews and welding tests for various certifications.

Read about the types of welding careers you can pursue with your skills. Ready to start a Professional Welding program? Contact us today about our welding certification preparation program.