TWS is a Great Training Option for Everyone

Learn more about how we can prepare you to advance your career.

When you want to saw a board apart, you use a clamp to keep the wood in place. Welders need more advanced welding tools than simple clamps in order to make certain that a welding project turns out as intended without flaws or damage. One of these tools—and one of the most practical tools in a welder’s arsenal—is a jig.

What Is a Jig?

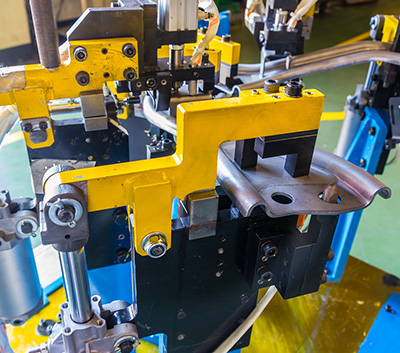

A jig is a large brace that keeps a welding project stable in the face of pressure, heat, motion, and force. A quality jig will streamline welding work by keeping parts together in a vice grip. Whether the welding is entirely manual, partially automatic, or fully robotic, a jig moves the workpiece while the tool remains stationary.

Jigs and Fixtures

While a jig is somewhat similar to a welding fixture, a fixture allows for both tool and workpiece to be moved together. Some jigs are attached to welding tables and have the function of a frame welding fixture; these may be known as frame welding jigs. The ergonomic design of all jigs minimizes the work needed to complete a task. 1

Have You Considered a Career in the Skilled Trades?

Fill out the form to recieve a no obligation info packet.

What to Look For In A Jig

Just like you want the frame of a car to be strong enough to handle the motion of the engine, suspension, and tires, you also want welding jigs that can take a lot of force and still keep going. A thorough welding program provides valuable information on what makes a jig a useful accessory for a job.

The jig should be stationary in the face of the welding tool, but should also be able to be moved in order to follow the weld. A decent jig may have several fixtures, making it possible to weld multiple pieces at the same time, or weld different shapes and metals on the same frame. A good jig should be versatile, adaptable, and able to comply with precision requirements of the welder. The degree of precision makes a great deal of difference: jigs need to be able to hold tolerance of only +/- .03 inches to keep metals steady and supportive. 2

Importance of Welding Jigs

Every welding job involves a number of different tools. It is very common to use welding jigs on a project due to their strength and dependability. Jigs make welding jobs easier, quicker, more accurate, more comfortable, and more cost-efficient.

1 – http://www.thefabricator.com/article/shopmanagement/what-to-look-for-in-railing-and-frame-welding-fixtures

2 – http://www.popsci.com/diy/article/2010-03/build-jig-improve-your-fabrications

This blog has been labeled as archived as it may no longer contain the most up-to-date data. For a list of all current blog posts, please visit our blog homepage at https://www.tws.edu/blog/