Duration:

7 months

Campus Availability:

- Tulsa, OK

- Jacksonville, FL

- Houston, TX

- Dallas Metro (Irving), TX

Upcoming Start Dates:

Jun. 11, 2025 & Aug. 8, 2025

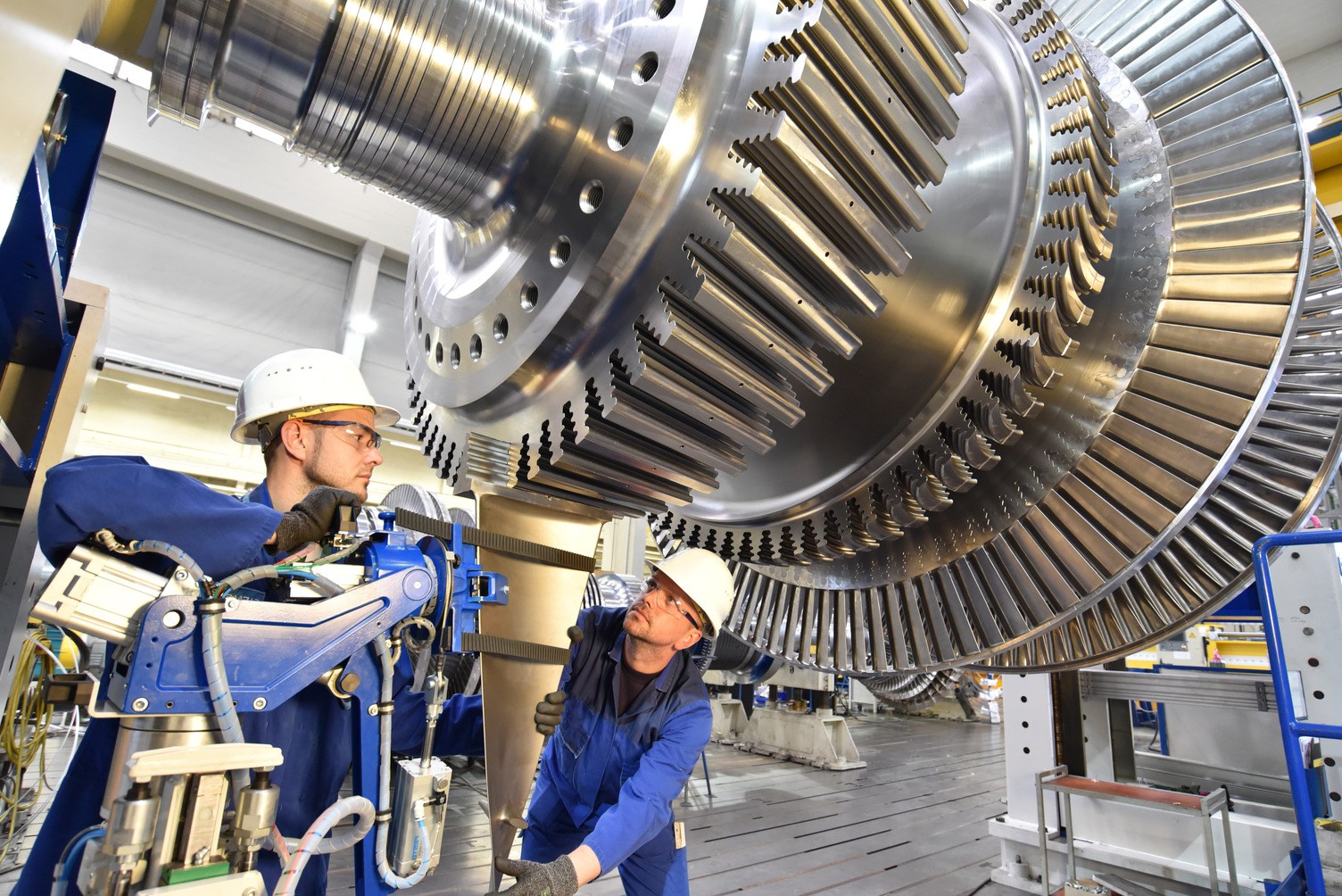

START TRAINING FOR A CAREER IN INDUSTRIAL MAINTENANCE

The Advanced Industrial Maintenance Technology program at Tulsa Welding School (TWS) uses expert instructors and hands-on courses to train students with the skills and knowledge necessary for career success.

Our in-depth industrial electrical maintenance training courses teach students the basics of mechanical and electrical principles, essential safety regulations, hazard awareness and mitigation, insight into manufacturing and distribution operations, and practical exposure to diagnosing, servicing and repairing common types of problems in related equipment.

Are you ready to start training for a career that can change your life?

The industrial maintenance technology training you’ll receive at TWS will empower you with the skills, knowhow and hands-on experience needed to safely service and repair common types of problems in related equipment.

The Advanced Industrial Maintenance Technology program is available at our Houston, TX campus, and you can earn a diploma with as little as seven months of training. You’ll be prepared to pursue career opportunities like:

- Industrial Machinery Mechanics

- Machinery Maintenance Technician

- Millwright

Employment is Expected to Grow for Industrial Maintenance in the US by 43,500 Jobs by 2033!i

Flexible Class Schedules

Morning and Evening Classes Available

TWS offers flexible schedules whether you are just graduating from high school, changing your career or transitioning from military to civilian life. Industrial maintenance classes schedules range from morning and evening, depending on the campus location.

We work hard to find the right program and the right schedule to help you succeed. Contact us for more information on upcoming class times and start dates for the Advanced Industrial Maintenance Technology program.

Advanced Industrial Maintenance Technology Class Start Dates

Houston, TX Class Schedules (Mon - Fri)

- Morning 7:00am - 12:00pm

- Evening 6:30pm - 11:30pm

Experiences & Opportunities

Resources for TWS Students

Virtual Tour

Take a virtual tour of our campuses! Explore the classrooms, labs and shop floor with our unique interactive experience.

Employer Relationships

TWS has relationships with major employers across the United States. Our dedicated Career Services team will be there to support you every step of the way after graduation.

The Right Tools for the Job

When you begin your education at TWS, we provide you with an extensive gear package. You get the high quality professional tools you need to succeed. Ask your Admissions Representative for more information about the gear package for your program.

Scholarship Opportunities

Learn more about what scholarship opportunities are available and how you might qualify for one. Start the process of applying for a scholarship today!

Ready to Move Forward?

All it takes to move forward is making that first step. Whether you need more information, schedule a tour or want to speak to someone, we’re with you every step of the way.

Are YOU ready to change your life?

Listen to these TWS graduates who changed theirs.

We all come from different walks of life, and different circumstances, but it’s the hard work we do and the blood sweat and tears put in to make us who we are today.

Tulsa Welding School gave these graduates the structure, confidence, and guidance they needed to make a difference in their lives. It only takes one decision to start the journey on a path towards a better career. A better Life.

Hear the stories of these TWS graduates and how they changed their lives:

Jonathan Garza

Coming from a place of darkness and addiction, Jonathan made the change he needed to get his life back on track for his family, career, and his stability. Professional Welding Graduate from our Houston campus - Hear his story on how TWS changed his life.

David Mclean

With so many options in front of him and no clear path ahead, David chose to invest in his life and make the decision to enroll at a trade school. TWS gave him the opportunities to be the best version of himself he could be. Professional Welding Graduate from our Jacksonville campus - Hear his story on how TWS changed his life

Cody Hudgens

Not basing his chances on luck, Cody took the opportunity of becoming a welder in his own hands after serving in the United States Marine Corps. TWS gave him the knowledge and skills he needed to take his passion to the next level. Professional Welding Graduate from our Tulsa campus - Hear his story on how TWS changed his life

Program Courses for Advanced Industrial Maintenance Technology

Introduction of Industrial Facilities

AIM101

This course will introduce students to the broad history of Industrial Maintenance and the facilities of the industry, up to and including the present-day landscape. An overview of the types of machinery and control methods used to gain efficiency and drive production will be presented.

By the end of this course students will have a basic knowledge of the careers and expectations of organizations across multiple disciplines as it relates to Industrial Maintenance Technicians in the industry today.

Requirements

- 4 Semester Credit Hours

- 64 Lecture Hours

- 36 Lab Hours

- 100 Total Contact Hours

- 20 Outside Prep Hours

Safety Compliance

AIM102

This course will introduce students to the many hazardous encounters they will need to anticipate while working in the industrial workspace. Introductions to LOTO, (Lock Out Tag Out), of electrical, mechanical, potentials of energy, as well as chemical sources of energy will be conducted.

Students will explore safety related regulations and standards that are mandated by governing bodies.

Other relevant topics include; OSHA 10 standards, Confined Space mandates, Lifting & Rigging safety, Fire Awareness and Prevention, Hazardous Chemical regulations and PPE, (Personal Protective Equipment).

Requirements

- 4 Semester Credit Hours

- 60 Lecture Hours

- 40 Lab Hours

- 100 Total Contact Hours

- 19 Outside Prep Hours

Metrology & Inspections

AIM103

In this course, students will learn the proper use and care of many measuring devices. Course participants will learn to interpret and record precise measurements, while understanding manufacturer’s tolerances and suggested applications of measurements.

This course will include both standard and metric readings and calculations, as many industrial facilities use both units of measure. Dimensional inspections will be a covered topic as well.

Requirements

- 4 Semester Credit Hours

- 50 Lecture Hours

- 50 Lab Hours

- 100 Total Contact Hours

- 15 Outside Prep Hours

DC & AC Electrical Applications

AIM104

This course will introduce students to electrical theory, application and units of measurement for DC and AC electrical quantities. This course is designed to teach students electrical circuit schematics and diagrams, symbols and calculations utilizing Ohm’s and Kirchhoff’s Law. Additional concepts that will be explored are; DC and AC power generation, consumption and measuring of Direct Current and Alternating Current quantities.

Activities in this course will require students to design, calculate, build, measure and troubleshoot DC electrical circuits in series, parallel and in combination. Additional activities in this course will require students to measure and/or calculate capacitance, impedance, transformation and sine waves.

Requirements

- 4 Semester Credit Hours

- 58 Lecture Hours

- 42 Lab Hours

- 100 Total Contact Hours

- 10 Outside Prep Hours

Advanced Electrical Applications

AIM105

This course will introduce students to an intermediate level of electrical theory, application and units of measurement for AC electrical quantities. This course is designed to teach students AC electrical circuit schematics and diagrams, symbols and calculations of multiple AC circuit components as applied to 3 phase, high voltage applications.

Additional concepts that will be explored are; 3 phase power controls, modification, rectification and conversion.

Activities in this course will require students to use recently acquired skills to perform high voltage terminations, phase to phase and line measurements of up to 480 volts, as well as programming and troubleshooting various control circuits with variable frequency drives, relays and programmable logic controllers.

Requirements

- 4 Semester Credit Hours

- 55 Lecture Hours

- 45 Lab Hours

- 100 Total Contact Hours

- 10 Outside Prep Hours

Materials Processing & Fabrication

AIM106

In this course, the student will learn to identify materials, such as; types of metals, types of composites and other workable materials. The selection, safety, and proper use of tooling, power tools and standard maintenance practices will be emphasized.

The student will learn fabrication techniques through practice and demonstrating their ability to read a print, take precise measurements, utilize tools and equipment for shaping materials by cutting, grinding, drilling, tapping, bolting and safety wiring. Students will complete standard inspections and learn to document findings and order up new equipment and components.

Requirements

- 3.5 Semester Credit Hours

- 40 Lecture Hours

- 60 Lab Hours

- 100 Total Contact Hours

- 12 Outside Prep Hours

Process Technology & Facility Maintenance

AIM107

This course will cover basic principles of refrigeration, heating and boiler operations with a primary focus on industrial and commercial equipment. Students will become familiar with using computer technology and instrumentation to operate equipment systems and relate that to the industrial process. Instruction and lab activities will include monitoring operating conditions like temperature, pressure, level, flow rates, and the use of testing equipment.

This course will also test students on the intermediate level of industrial facility maintenance, as it relates to; main building power, switchgear, subpanels, distribution of power, fuses, transformers, single phase and 3-phase breakers and disconnects, automation & robotics basics, and CMMS, (Computerized Maintenance Management Systems).

Requirements

- 4 Semester Credit Hours

- 60 Lecture Hours

- 40 Lab Hours

- 100 Total Contact Hours

- 19 Outside Prep Hours